Condition monitoring ( CM) is the process of monitoring a parameter of condition in machinery (vibration, temperature etc.), in order to identify a significant change which is indicative of a developing fault. It is a major component of predictive maintenance.

The use of condition monitoring allows maintenance to be scheduled, or other actions to be taken to prevent consequential damages and avoid its consequences. Condition monitoring has a unique benefit in that conditions that would shorten normal lifespan can be addressed before they develop into a major failure.

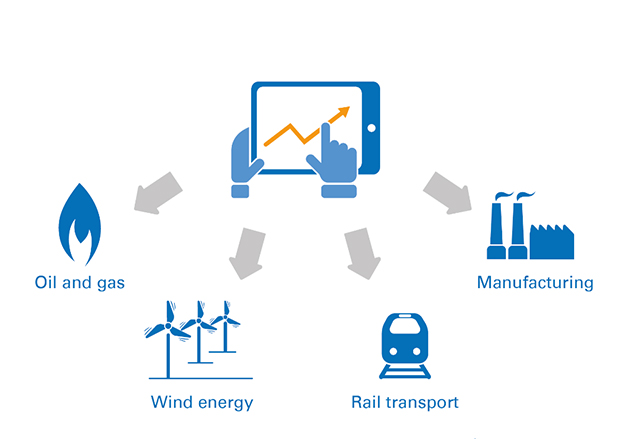

Condition monitoring techniques are normally used on rotating equipment, auxiliary systems and other machinery (compressors, Pumps, electric Motors, internal combustion engines, presses), while periodic Inspection using None destructive Test (NDT) techniques and fit for service (FFS)[,evaluation are used for static plant equipment such as Steam Boilers, Piping and Heat Exchangers.

Condition monitoring (CM) and Condition Based Maintenance (CBM) are essential elements of a risk based maintenance strategy.

During The design stage of new oil and gas installations a significant amount of time and resource will be devoted to the development of a planned maintenance programme.

This will entail the application of a risk based analysis process (such as RCM) that considers equipment criticality, failure modes and effects (FMEA) and failure characteristics to enable the planned maintenance routines to be formulated.

A maintenance programme developed using a risk based approach will, by

definition, require the support of an effective condition monitoring / condition based maintenance approach.

The value associated with condition based maintenance lies in the use of condition information to control and focus maintenance activities for production and safety critical plant.

Condition Based Maintenance Management’s CBM team specialize in the implementation and operation of machinery condition monitoring programs to optimize the benefits gained from adopting a condition based maintenance strategy.

Our clients recognize that through life costs can be reduced by maintaining machinery under the Preventative Maintenance Techniques with Condition Monitoring Method’.

CBMM is experienced to provide the condition monitoring element of this method to clients for inclusion in the Owners Annual Report.

Condition Based Maintenance Management personnel are also highly experienced in providing these services in line with international certification bodies requirements.

Pishgaman Trade and Sustainable Development Company was registered in 2006 with the mission of providing engineering services and equipment for the country’s infrastructure industries, especially the oil industry. This company has a mission to use and train efficient technical and engineering personnel and graduates.